A CO2 leak detector is a specialized device that measures carbon dioxide concentrations to identify system leaks using CO2, such as beverage dispensers, refrigeration units, and industrial equipment. It provides early warning through digital readings and alarms when CO2 levels exceed safe thresholds. They are also used to undertake a indoor air quality assessment for healthy indoor human exposure to CO2 gas.

Pros |

Cons |

|

✅ Accuracy: Real-time monitoring of indoor CO2 concentration levels. ✅ Health Safety: Helps maintain optimal indoor air quality standards. ✅ Versatility: Suitable for homes, offices, schools, and public spaces. ✅ User-Friendly: Easy-to-read displays with clear concentration indicators. |

⛔ Calibration: Requires periodic sensor calibration for accuracy. ⛔ Placement: Sensor location critical for accurate readings. ⛔ Cost: Quality monitors require significant initial investment. ⛔ Maintenance: Regular cleaning and sensor checks are needed. |

What Is the Best CO2 Leak Detector?

The Forensics Detectors CO2 leak detector stands out as a top choice for reliable carbon dioxide detection, combining accuracy with user-friendly features. Other top CO2 leak detectors are listed below.

- Forensics Detectors CO2 Leak Detector

- Elitech CO2 Leak Detector

- Accutools CO2 Leak Detector

- Inficon CO2 Leak Detector

- CO2 Meter CO2 Gas Leak Detector

Is CO2 Dangerous?

Yes it is.

A CO2 leak can be dangerous, especially in indoor confined rooms and spaces. CO2 gas can accumulate and increase in concentration. When that happens, the CO2 gas can displace oxygen and lead to asphyxiationIn low concentrations, carbon dioxide is generally not harmful to humans. However, in enclosed or poorly ventilated areas, such as in buildings or confined spaces, a CO2 leak can cause the concentration of the gas to rise to dangerous levels. Breathing in high levels of carbon dioxide can result in symptoms such as dizziness, shortness of breath, headache, confusion, rapid breathing, increased heart rate, and in extreme cases, loss of consciousness or death.

Who Uses a CO2 Air Quality and Leak Detector?

How to Test for CO2 Air Quality?

To test for a CO2 (carbon dioxide) leak, you can follow these general steps:

- Ensure Safety: Before conducting any tests, ensure that you are in a well-ventilated area or wear appropriate personal protective equipment (PPE) if necessary. If you suspect a significant CO2 leak or are experiencing symptoms of carbon dioxide poisoning, evacuate the area and seek fresh air immediately. Don't forget that CO2 is heavier than air, so if you are in a shaft or confined space, take extra precautions.

- Use a CO2 Leak Detector: Acquire a CO2 leak detector and use it at suspected leakage locations to pinpoint the increase in CO2 concentration. Leaks usually occur at gas lines, CO2 cylinders, junctions, and connectors.

- Monitor the CO2 ppm Readings: Allow the CO2 detector sufficient time to sample the air and provide accurate readings. Monitor the detector's display or indicators for any changes in carbon dioxide levels. If the detector has an alarm function, ensure that it is activated and set to an appropriate threshold.

- Leak fixing: If a leak has been found. Take note of its location and tag the location. Ensure the breathable air does not exceed 5000ppm (otherwise evacuate). Address the leakage with an appropriate engineer or technician.

What Does CO2 Gas in Air Smell Like?

CO2 gas is a colorless, odorless gas, so it does not have a smell. This makes it difficult to detect a CO2 gas leak without the use of specialized equipment such as a CO2 leak detector.

How to Test for a CO2 Gas Leak?

If you suspect you have a CO2 gas leak, you should use a tool such as a CO2 Leak Detector.

- Begin by turning on the CO2 Leak Detector and allowing it to start operating after the countdown.

- Next, perform a quick bump test to ensure the analyzer is functional. You can do this by breathing at the input port. The point here is to confirm the CO2 Leak Detector is indeed operating.

- Once you have completed the bump test, take the CO2 Leak Detector and scan the area of interest, moving about 2 seconds per inch. Be patient and thorough to ensure you capture any CO2 gas.

- Typical areas of leakage occur around connections, valves, line bends, and junctions. Make sure to check these locations.

- Observe the detector's response. The units have a digital readout in PPM so it is very sensitive.

- If you have confirmed a CO2 gas leak, ensure you take appropriate action to maximize safety.

How Long Does the CO2 Sensor Last?

The lifespan of a CO2 (carbon dioxide) NDIR (Non-Dispersive Infrared) sensor last between 5 to 15 years. Generally, CO2 NDIR sensors are designed to have a long operational life with stable performance. The sensor's lifespan is influenced by factors such as operating temperature, humidity, exposure to contaminants, and the frequency of calibration and maintenance.

How often should I test or calibrate my CO2 Air Quality Analyzer?

Calibration should be performed between 6 to 12 months.

Will a CO2 Gas Leak set off Carbon Monoxide Detector?

No, a CO2 gas leak will not set off a carbon monoxide (CO) detector. Carbon monoxide detectors are specifically designed to detect and alert occupants to the presence of carbon monoxide gas. Carbon monoxide and carbon dioxide are two distinctly different gases. Don't get confused.

How Does a CO2 Gas Analyzer Work?

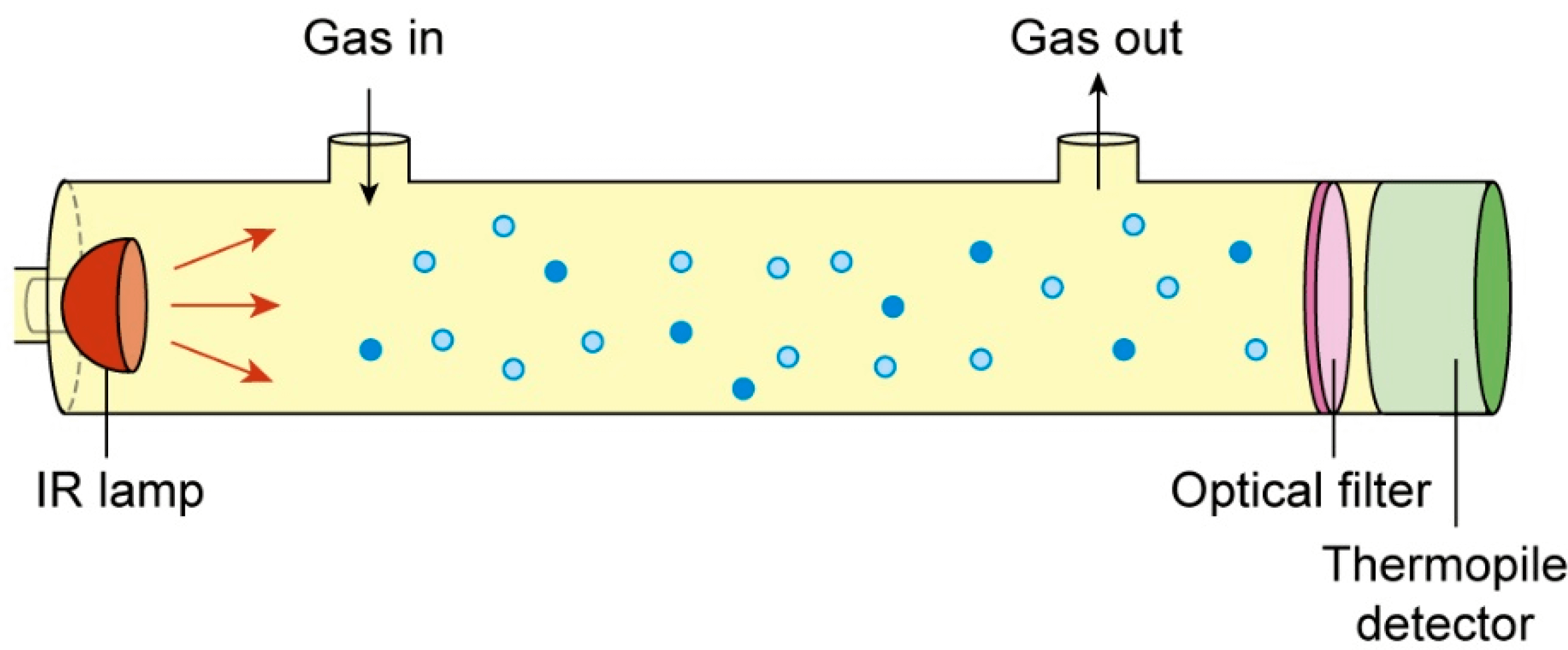

A CO2 gas analyzer typically uses a sensing technology called NDIR to detect the presence of carbon dioxide gas in the surrounding environment. Here's a basic overview:

- Infrared Light Source: The detector contains an infrared light source that emits a specific wavelength of infrared light, typically in the range of 4.2 to 4.4 micrometers. This wavelength is selectively absorbed by carbon dioxide molecules.

- Gas Sample Collection: The detector collects a sample of the surrounding air or gas mixture through an inlet or sampling port. For the CO2 Leak Detector, the unit has a pump that forces the air in the chamber for a faster leak detection response.

- Infrared Sensor: The detector incorporates an infrared sensor that consists of a detector element, typically made of pyroelectric or thermopile material. The sensor is designed to detect the infrared light after it has interacted with the gas sample.

- Absorption Measurement: When the infrared light passes through the gas sample, carbon dioxide molecules absorb some of the light at the specific wavelength emitted by the light source. The amount of light absorbed is directly proportional to the concentration of carbon dioxide present in the sample.

- Signal Conversion: The infrared sensor measures the intensity of the light that has passed through the gas sample and converts it into an electrical signal. The magnitude of the electrical signal corresponds to the amount of absorbed light and, in turn, indicates the concentration of carbon dioxide in the environment.

- Threshold and Alarm: The CO2 leak detector is typically programmed with a predetermined threshold or alarm level for carbon dioxide concentration. If the detected concentration exceeds this threshold, the detector triggers an audible and/or visual alarm to alert individuals of the potential CO2 leak.

How Should I Store my CO2 Air Quality Analyzer?

To ensure maximum sensor life and accurate measurements upon operation, it is recommended to store the CO2 Leak Detector in a moderate environment with a humidity level of 50%RH and a room temperature of approximately 70F. The unit should be kept in the hard waterproof case it was sold with for optimal storage conditions.

CO2 Air Quality History

- The exploration of CO2's impact dates back to the seventeenth century when Mayow proposed that igneo-aerial particles generated by candles were responsible for harming animals.

- In the eighteenth century, Lavoisier attributed these effects to CO2, which was then considered the cause of physiological issues linked to poor air quality. CO2 served as an indicator of whether the air was stale or fresh, rather than oxygen deficiency being the primary concern.

- In the nineteenth century, Max Josef von Pettenkofer challenged the idea that CO2 caused discomfort. Instead, he and Saeltzer suggested that the presence of organic material from human skin and lungs was responsible for negative effects attributed to poor ventilation. They proposed using CO2 levels as a surrogate for vitiated air and as an indicator of harmful airborne substances of unknown origin. Pettenkofer recommended 1000 ppmv of CO2 as a marker of insufficient indoor ventilation and 700 ppmv for bedrooms.

- In the early twentieth century, studies by Billings, Hermans, Flugge, Hill, and others showed that discomfort in poorly ventilated rooms was caused by warmth combined with odors in crowded spaces. Experiments with elevated CO2 levels (3% or 4%) and reduced oxygen levels (down to 17%) did not demonstrate significant negative effects, except for increased breathing rate and the need for cooling.

- Later research by Lemberg and Yaglou revealed that the response to human body odor could serve as a criterion for ventilation. Perceived odor intensity was used to establish ventilation rate requirements of approximately 7.5 to 10 L/s (15 to 20 cfm) per person, as proposed by Persily in 2015. During this time, CO2 was considered a marker of body odor perception, as humans emit both CO2 and bioeffluents in relation to their metabolism.

- Studies conducted in the latter part of the twentieth century by Fanger, Cain, and Iwashita, which used the acceptability of perceived air quality as the criterion for ventilation requirements, confirmed the findings of Yaglou and Lemberg. The research on body odor perception was utilized by ASHRAE and the European Committee for Standardization (CEN) to develop ventilation standards.

- The 1989 edition of ASHRAE's ventilation standard, Standard 62 (later revised to Standard 62.1), initially set a CO2 limit of 1000 ppmv, but this was subsequently removed from later editions due to common misinterpretation.

What is the Difference Between CO2 and CO Leak Detectors?

CO and CO2 are two different gases. Often, these two gases are confused and mixed up between people and can be dangerous. CO2 is carbon dioxide, and CO is carbon monoxide. Our carbon monoxide leak detector is also available.

Can I smell a CO2 Leak?

CO2 is odorless so your nose will never pick up a CO2 leak.

Conclusion

- A CO2 air quality and leak detector is a device designed to find CO2 gas leaks along various gas lines and connections.

- For maximum sensitivity, make sure your CO2 analyzer has 1ppm resolution.

- They help identify and locate potential CO2 leaks before they become a health hazard as CO2 can accumulate and deplete the oxygen in an indoor space.

- A CO2 air quality and leak detector should be used with an appropriate pinpoint probe, built-in pump (to increase detection speed), and display CO2 concentration in ppm.

- Be patient and slow when using a CO2 gas analyzer. It can take some time for good consistent measurements and dont forget not to exhale next to the device (exhalation distorts ppm CO2 readings).

About The Author

Dr. Kos Galatsis ("Dr.Koz") is the President of FORENSICS DETECTORS where the company operates from the scenic Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years.

Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems. Dr. Koz also loves spending time with his wife and his three children going to the beach, grilling burgers, and enjoying the outdoors.

Read more about Forensics Detectors here.

Email: drkoz@forensicsdetectors.com

Phone: +1 424-341-3886