Carbon dioxide monitors (CO2 monitors) serve multiple critical functions, from process control in fermentation and chemical manufacturing to safety monitoring in confined spaces and leak detection. They're essential for environmental control in greenhouses and HVAC systems, quality assurance in food packaging, and ensuring regulatory compliance in workplace safety. These devices help maintain optimal CO2 levels while protecting workers and processes.

What Is The Best CO2 Monitor for Industrial Safety?

There are many CO2 monitors for industrial safety. Several top sellers are listed below.

- Forensics Detectors CO2 Monitor | 0-5000 ppm

- Co2meter Carbon Dioxide Fixed Wall Mount

- CO2METER® 7000 Series CO2 Safety

- Macurco CO2 Wall Mount FIxed CO2 Monitor

What are the Best CO2 Levels?

Maintaining indoor CO2 levels as close to 410 ppm, which corresponds to outdoor CO2 concentrations, is the ultimate objective in air quality. It is important to ensure that indoor CO2 does not exceed 1000 ppm. If it does, it is imperative to introduce additional fresh air to renew the indoor environment effectively.

The American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) and other organizations suggest maintaining indoor CO2 levels below 700 ppm above the outdoor air level, which is between 1000 and 1100 ppm. Therefore we recommend the first alarm point in any CO2 monitor to be set at 1000ppm.

Case Study 1: CO2 for Breweries

This study demonstrates the impact of venting fermentation CO2 and unintentional CO2 venting during CO2 storage tank filling. This study is undertaken inside an Australian craft brewery.

The CO2 Brewery Problem

Breweries provide a prime example of how CO2 is generated as a by-product of fermentation, where yeast converts glucose into alcohol and CO2, a critical component of beer production. While larger breweries can capture and reuse fermentation CO2 for beer carbonation, this technology is often financially out of reach for smaller breweries.

CO2 can exhibit a safety concern in a brewery due tot he CO2 generated by the fermentation process. Therefore the necessity of CO2 monitoring for breweries.

Instead, small or medium-sized breweries typically vent CO2 from fermentation tanks directly into the indoor environment, while CO2 for carbonation is purchased separately and pumped into large indoor/outdoor storage tanks via delivery trucks. However, this venting process, along with unintentional venting during CO2 storage tank refilling, poses a risk that could cause indoor CO2 levels to exceed safe limits. Therefore, adequate CO2 monitoring systems must be in place to ensure safe IAQ.

CO2 Brewery Results

This study revealed that indoor CO2 levels can rise significantly, with a maximum level recorded in excess of 18,000 ppm and maximum time periods exceeding 1000 and 10,000 ppm equivalent to 425 and 26 minutes, respectively.

This study showed that extremely high CO2 levels can exist in breweries making it a very dangerous occupational space. It also dentified differences in measured CO2 levels at different times and locations throughout the brewery, highlighting the inadequacy of just having a single CO2 monitor. Instead, a network of portable or wearable CO2 detectors is more suitable and recommended for best safety.

Case Study 2: CO2 for Hydroponics

One of my favorite CO2 studies investigated the impact of varying CO2 concentrations on the growth of winter wheat using controlled growth chambers.

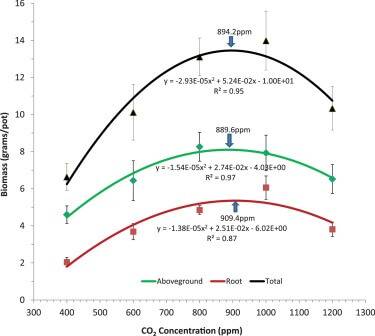

The CO2 levels were set at 400, 600, 800, 1000, and 1200 ppm, respectively. The study observed that an initial increase in CO2 concentration significantly enhanced winter wheat growth, thanks to the CO2 fertilization effect. However, this effect diminished with further increases in CO2 levels, indicating an optimal CO2 concentration for different aspects of growth.

The optimal CO2 concentrations identified were approximately 889.6 ppm, 909.4 ppm, and 894.2 ppm for aboveground, belowground, and total biomass, respectively, while leaf photosynthesis showed an optimum at 967.8 ppm.

Beyond these optimal points, higher CO2 concentrations had adverse effects. They reduced leaf stomatal density, length, and conductance, and also altered the spatial distribution pattern of stomata on leaves.

Optimal CO2 levels for growing wheat. Results indicate between 800 to 1000 ppm is best. Beyond that, negative effects are incurred. In fact very similar for other crops!

Is CO2 used in Beer Draught Systems?

Yes, CO2 is used in the draught beer system to ensure freshness and propel the beer from the keg to the tap.

Carbon dioxide is supplied in CO2 tanks which is stationed at the retail site and refilled as required. This system is it now popular among average-sized bars and restaurants for their soda and beer systems and can be a cost-effective option for many.

The amount of CO2 stored can impact the potential for danger. With a small cylinder, if there is a CO2 leak, once the gas runs out, it is less likely to produce harm. However, bulk tanks contain significantly larger amounts of CO2, which can pose a lethal threat if there is a leak in the cooler.

Here are some guidelines and precautions to ensure safe handling of carbon dioxide:

- Early Detection with CO Monitors: CO2 detection monitors equipped with alarms can be a valuable preventive measure. Some alarms have both an audible signal and a strobe light to alert individuals. These devices are relatively inexpensive and can be lifesaving. It is important to test and ensure that all alarms are functioning correctly at least once a year.

- Adequate Ventilation: Walk-in coolers can be updated or installed with a proper ventilation system to reduce the risk of gas accumulation to hazardous levels in an enclosed space. This means ensuring fresh air from the outdoors is entering the confined space.

- Easy Exits: It is crucial to ensure that the cooler door is functioning correctly from both the inside and outside and is easy to exit in case of an emergency.

-

Secure and Organized Storage: Keeping the cooler tidy and organized can also help prevent accidents such as trips or falls. A CO2 container should always be securely fastened to a wall to avoid accidental tipping and local codes for tank storage should be followed.

CO2 Air Circulation Vents

It is imperative for any CO2 monitor to have abundant air vents and openings to allow for the surrounding CO2 molecules to quickly reach the CO2 sensor. This design mechanism has a direct impact in how fast your CO2 monitor will be able to reliably react and stabilize the CO2 readings that approximate the same CO2 one is inhaling. The back of the unit also has the ON / OFF button.

FUN FACT!

Did you know many people call us to ask for a CO2 detector, when in fact they meant to ask for a CO (Carbon Monoxide) detector. Dont get confused. CO2 and CO2 are very different gases and one detector does not detect the other 🙁

When do I Calibrate my CO2 Monitor?

We recommend calibrating your CO2 monitors every year.

Does CO2 Have A Distinctive Smell That Workers Should Be Aware Of?

No, industrial-grade CO2 is completely odorless.

Conclusion

- CO2 monitoring is necessary for various industries such as breweries, wine, hydroponics, and many others.

- CO2 Monitors ensure safety and can also be used to control the environmental CO2 level by switching the CO2 supply or increasing ventilation.

- CO2 monitors that are industrial spec are more expensive since they are more robust and typically have high-power relay switch functions.

- Warning: Do not confuse carbon dioxide (CO2) with carbon monoxide (CO) monitoring. They are completely different gases.

About The Author

Dr. Kos Galatsis ("Dr.Koz") is the President of FORENSICS DETECTORS where the company operates from the scenic Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years.

Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems. Dr. Koz also loves spending time with his wife and his three children going to the beach, grilling burgers, and enjoying the outdoors.

Read more about Forensics Detectors here.

Email: drkoz@forensicsdetectors.com

Phone: +1 424-341-3886