A combustible gas detector is a safety device designed to measure the concentration of explosive or flammable gases in the air. It works by detecting the presence of these gases relative to their Lower Explosive Limit (LEL). This tool is crucial for identifying potentially dangerous leaks of various combustible gases, including natural gas, butane, propane, and other hydrocarbons. It's also effective in detecting vapors from flammable solvents and alcohols. By alerting users to the presence of these gases before they reach dangerous levels, combustible gas detectors play a vital role in preventing accidents and ensuring safety in both industrial and residential settings.

Pros |

Cons |

|

✅ Safety: Protects users from dangers explosive and flammable gas concentrations. ✅ Compliance: It is a must have for various professionals. ✅ Real-time monitoring: Catalytic bead sensors are employed to provide immediate and fast responses. |

⛔ Cost: Can get expensive, but some low cost options are available. ⛔ ppm or %LEL: Make sure to purchase the correct unit. Some users need ppm, others need %LEL measuring scale. ⛔ Training required: Gas detectors require calibration, bump testing and regular maintenance to ensure maximum safety. |

Top 4 Best Combustible Gas Detectors?

Top 4 best combustible %LEL gas detectors used in industry include the following:

What is a Combustible Gas detector?

A combustible gas detector is a safety device designed to identify the presence of flammable gases in an environment. It works by measuring gas concentrations relative to their Lower Explosive Limit (LEL), which is the minimum concentration needed for ignition. These detectors are crucial in various settings, including industrial facilities, homes, and confined spaces.

Examples of Combustible Gases?

The most popular combustible gases include methane (natural gas), propane, butane, hydrogen, acetylene, ethane, ethylene, carbon monoxide, gasoline vapors, and diesel fuel vapors. Other common flammable gases are ethanol, methanol, ammonia, benzene, toluene, hexane, pentane, isopropyl alcohol vapors, ethyl acetate, and xylene.

What are the different types of Combustible Gas Detectors?

There are primarily 4 different combustible gas detectors that are available. These are made for different combustible and flammable gas detection application.

Personal Safety Combustible Gas Detectors (measure in %LEL)

These units are used for continuous personal protection and are attached to the belt of body of industrial workers for occupational safety and confined space entry. Most often using the %LEL measuring scale.

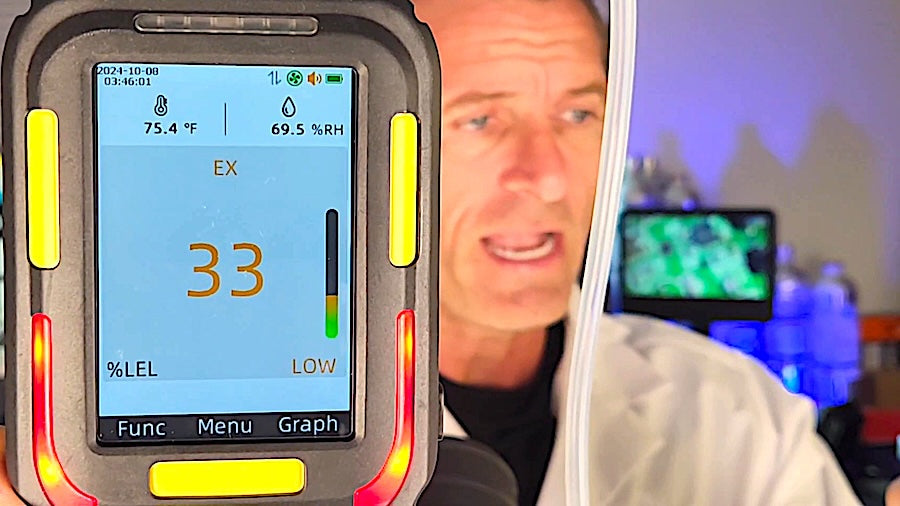

Gas Leak Combustible Gas Detectors - Explosimeters (measure in %LEL)

These units are used for indoor spaces, tanks, silos and others confined spaces for explosive, combustible or flammable situations. Used mainly with a detector and probe (with pump). Sometimes there are called explosimeters.

Gas Leak Gooseneck Combustible Gas Detectors (measure in ppm)

These are popular units used by most people to find natural gas leaks at home, propane leaks and other combustible gas leaks. The units is made for small leaks so a more sensitive semiconducting metal oxide gas sensor is used to present the detect concentration in parts per million (ppm). These units are called gas leak detectors.

4 Gas Monitors (EX LEL with other gases)

4 gas monitors are popular personal safety devices used in many industries for occupational safety. 4 gas monitors are often used for confined space entry and includes 4 sensors. CO, O2, H2S and EX. The EX sensor is typically a catalytic bead type sensor detecting and measuring in the %LEL range and most commonly calibrated to methane.

Combustible Gas Sensors?

There are two primary combustible gas sensor that dominate the market and are found in most combustible gas detectors.

1. Catalytic Bead Sensors (most common for %LEL range)

A catalytic bead sensor is a device used to detect combustible gases, and probably the most common type of combustible gas sensor that exists when detecting in the %LEL range. It consists of two beads: an active bead coated with a catalyst and an inactive reference bead. When exposed to flammable gases, the active bead oxidizes them, causing a temperature increase. This change in temperature alters the bead's electrical resistance, which is measured and compared to the reference bead. The difference in resistance is proportional to the gas concentration, allowing for accurate detection of combustible gases.

2. Semiconducting Metal Oxide Sensor (most common for ppm)

A SnO2 Semiconducting Metal Oxide gas sensor is a device that detects the presence of gases in the air. It uses a layer of tin oxide (SnO2), a semiconductor material. When gases come into contact with the SnO2, its electrical conductivity changes. By measuring this change, the sensor can determine the type and concentration of the gases present. This detector is often used for gas leak detection that one looks to measure in the part per million (ppm) range. These sensors are much more sensitive than catalytic bead gas sensors.

How To Use Combustible Gas Detector?

There are two ways to use a combustible gas detector.

1. Personal Exposure Protection (passive, alarming when ambient is dangerous)

Ensure the device is properly calibrated and functioning correctly. Turn on the detector in a clean air environment and allow it to warm up and zero itself. Clip it to your body. Belt clip or chest pocket. The unit will alarm when the environmenet is dangerous.

1. Gas Leak Detection (active, point sampling and ambient areas)

Ensure the device is properly calibrated and functioning correctly. Turn on the detector in a clean air environment and allow it to warm up and zero itself. When testing an area, move the detector slowly and steadily, as gases can be present in pockets or layers. For leak testing in pipes, move the sensor 1inch per second. Pay attention to the display and any audible or visual alarms. Note that begin testing at the floor level and move upwards, as many combustible gases are heavier than air. When investigating potential leak sources, move the detector from areas of lower concentration to higher concentration to pinpoint the leak.

What is a Combustible Gas Leak Detector?

A combustible gas leak detector is the same as a combustible gas detector, but in this case, it refers to the gooseneck version that is specifically made for Gas Leak applications.

Are Gas Leak Detectors the same as a Combustible Gas Detector?

Gas leak detectors are versatile devices capable of identifying both combustible and non-combustible gases. They can detect a wide range of substances, including benzene, ethylene oxide, gasoline, industrial solvents, jet fuel, lacquer, acetone, alcohol, hydrogen sulfide, propane, and various refrigerants. These detectors serve two primary functions: pinpointing the source of existing leaks and verifying the absence of leaks in a given area. This dual capability makes them essential tools for safety and maintenance in various industrial, commercial, and residential settings.

What Is The Limitation Of A Combustible Gas Detector Of Catalytic Combustion Type?

The most important for catalytic sensors is that these sensors require oxygen to function properly, making them unreliable in oxygen-deficient environments. (less than 10 %vol) High gas concentrations can damage the sensor, potentially leading to inaccurate readings or sensor burnout. Catalytic sensors may also experience drift over time, necessitating regular calibration. They can be cross-sensitive to other combustible gases, potentially giving false readings if multiple gas types are present. These detectors typically have a limited lifespan of 2-5 years due to sensor degradation.

What Are Combustible Gases?

Combustible gases are flammable gaseous substances that can ignite and burn when mixed with air (oxygen) in the presence of an ignition source. These gases are characterized by their ability to reach their flash point and ignition temperature relatively easily under normal atmospheric conditions. Common examples include methane (natural gas), propane, butane, hydrogen, acetylene, and various hydrocarbon vapors. In industrial settings, combustible gases can also include by-products of manufacturing processes or decomposition of materials. The danger of combustible gases lies in their potential to form explosive mixtures with air within specific concentration ranges, known as the explosive range or flammable range. This range is defined by the Lower Explosive Limit (LEL) and Upper Explosive Limit (UEL). Combustible gases pose significant safety risks in many industries and domestic settings, necessitating careful monitoring, proper ventilation, and safety measures to prevent accidents, fires, and explosions.

What Is The Difference Between Combustibles, Flammable And Explosive Gases?

While often used interchangeably, there are subtle differences between combustible, flammable, and explosive gases. Combustible gases are those capable of burning when mixed with air and ignited, but they typically have a higher ignition point. Flammable gases are a subset of combustible gases that ignite easily at ambient temperatures, generally with a flash point below 100°F (37.8°C). All flammable gases are combustible, but not all combustible gases are flammable. Explosive gases refer to gases that can rapidly expand and release energy in a violent manner when ignited. In practice, many gases can be both flammable and explosive depending on their concentration in air. The key difference lies in how quickly and violently the combustion occurs. Flammable gases burn, while explosive gases detonate.

What Is the Difference Between ppm and %vol Gas Leak Detector Readings?

The typical scales of concentration for combustibles such as methane or propane are ppm and %vol. Both of these values are interchangeable.

Conversion Example

Methane % value = (methane ppm / 1,000,000) x 100%

For example, if we have 5,000 ppm of methane, then we obtain:

Methane % value = (5,000 / 1,000,000) x 100%

Methane % value = 0.5%

Quick Conversion from ppm to %vol

100 ppm = 0.01%

1,000 ppm = 0.1%

10,000 ppm =1%

100,000 ppm =10%

1,000,000 ppm =100%

What Is the Difference Between ppm and %LEL Gas Leak Detector Readings?

%LEL is very different than %vol. %LEL represents a percentage of the lower explosive limit of a particular combustible.

Each combustible has a different explosive limit in air and different low explosive levels (LEL).

For example, methane will explode in air at 5% volume (which is 50,000 ppm). This is called te 100% Lower Explosive Limit. In other words, 100% LEL = 5% volume. When the methane concentration reaches 100% LEL, the gas will explode if an ignition source is present. For propane, 100% LEL = 2.1% volume, and for hydrogen, 100% LEL = 4.0% volume.

So if our gas detector is reading 5% LEL and it has been calibrated to methane, then 5% of [5%vol] = 0.25% vol or 2,500 ppm.

What Are Correction Factors for %LEL and Combustible Meters?

Catalytic bead sensors, also known as LEL (Lower Explosive Limit) sensors, are versatile devices capable of detecting various combustible gases and vapors. These sensors employ a diffusion barrier to regulate gas flow to the catalytic bead, resulting in heightened sensitivity to high-diffusivity compounds. Consequently, they respond more readily to small molecules like hydrogen and methane compared to heavier substances such as kerosene.

While calibrating with the specific gas of interest is ideal, Correction Factors (CFs) have been established to allow quantification of numerous chemicals using a single calibration gas, typically methane. This approach enables efficient and adaptable gas detection across a wide spectrum of combustible substances.

There are a few ways to accommodate correction factors.

- Option 1 - Readout Adjustment. Operate your gas leak detector as normal. Let us assume it has been factor calibrated to methane (which is industry standard). So if the device reads 10% LEL registering from a ethanol source, we will use the correction factor for propane, which is 1.8. Multiply 10% LEL to ethanol CF (1.8), which gives 18% LEL. This means the corrected (real) reading is 18% LEL.

- Option 2 - Calibration Adjustment. Calibrate the unit with methane (factory standard). Assume you are calibrating it to 25% LEL methane. You are certain you will exclusively use it for an ethanol detection (for example). In that case, your span calibration point will not be 25% LEL but will be 25% LEL x 1.8 = 45% LEL. The unit has been calibrated with and adjustment to read and display %LEL of ethanol.

- Option 3 - Alarm Set point Adjustment. Now assume you do not want to re-calibrate the unit to take into consideration the correction factor. You can do the inverse which is adjust the alarm set point to accommodate the correction factor. In this case, your alarm point will not be 25% LEL (methane) but instead will be 25% LEL x (1/1.8) = 14% LEL.

The below table includes some common combustible gases and their correcting factors. These and others can be found here.

Gas |

Correcting Factor (Multiply) |

| Acetone | 1.9 |

| Ammonia | 1.0 |

| Ethanol | 1.8 |

| Ethylene Oxide | 1.7 |

| Gasoline | 2.6 |

| Hydrogen | 1.0 |

| Isopropanol | 2.2 |

| Propane | 1.4 |

| Toluene | 2.4 |

What is the Maintenance Schedule for a Combustible Detector?

Most combustible gas detectors require the following maintenance schedules that are important to ensure, operation, accuracy, and safety.

- Bump Testing (weekly to monthly, sometimes even daily)

- Calibration Schedule (every 12 months)

- Replacement Schedule (2-3 year sensor replacement, some may be extended up to 5 years, check with the manufacturer)

Can Different Combustible Gas Be Identified By Their Distinctive Smells?

Most pure combustible gases are naturally odorless. However, manufacturers add distinctive odorants like mercaptan to help detect dangerous leaks through smell for safety purposes.

Conculsions

In conclusion, combustible gas detectors are essential safety devices that measure the concentration of flammable gases relative to their Lower Explosive Limit (LEL). They come in various types, including personal safety detectors, gas leak detectors, and 4-gas monitors, utilizing either catalytic bead or semiconducting metal oxide sensors. While these detectors offer crucial safety benefits and real-time monitoring, they require proper training, regular maintenance, and calibration. Understanding the differences between combustible, flammable, and explosive gases is vital for their effective use. Despite some limitations, combustible gas detectors remain indispensable tools for preventing accidents in both industrial and residential settings.

About The Author

Dr. Kos Galatsis ("Dr.Koz") is the President of FORENSICS DETECTORS where the company operates from the scenic Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years.

Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems. Dr. Koz also loves spending time with his wife and his three children going to the beach, grilling burgers, and enjoying the outdoors.

Read more about Forensics Detectors here.

Email: drkoz@forensicsdetectors.com