Nitrogen gas detectors are essential tools for identifying elevated levels of nitrogen in various settings, such as nitrogen storage, purge systems, and leak detection. However, these detectors often actually measure oxygen levels instead of directly detecting nitrogen. Gas detection focused on oxygen is more meaningful, as oxygen is vital for human life, and its displacement by increased nitrogen concentrations can be dangerous. By monitoring oxygen levels, nitrogen detectors can alert personnel to potential risks associated with nitrogen-induced oxygen depletion. Implementing reliable nitrogen gas detection is crucial for ensuring personal protection and maintaining a safe working environment in areas where nitrogen is present, preventing the adverse health effects of oxygen deficiency.

Pros |

Cons |

|

✅ Nitrogen detectors are most often actually oxygen detectors. ✅ Nitrogen is an inert gas and has the potential to displace oxygen quickly. Nitrogen gas expands 700 times more than its liquid volume. Thankfully, oxygen detection is easily detected using electrochemical sensors. ✅ Many nitrogen gas leak detectors are available for less than $599. |

⛔ Can be confusing if one needs a nitrogen detector or a oxygen detector. ⛔ Sensors typically last from 24 to 36 months (some work for over 5 years). ⛔ True nitrogen sensors are made using ultrasonic or thermal conductivity sensors. |

What Is the Best Nitrogen Gas Detector?

There are many nitrogen gas detectors on the market, including electrochemical (ppm) and or zirconia sensor based analyzers. The reputable brands include the following:

Nitrogen Gas Detectors

1. Nitrogen Gas Leak Detector

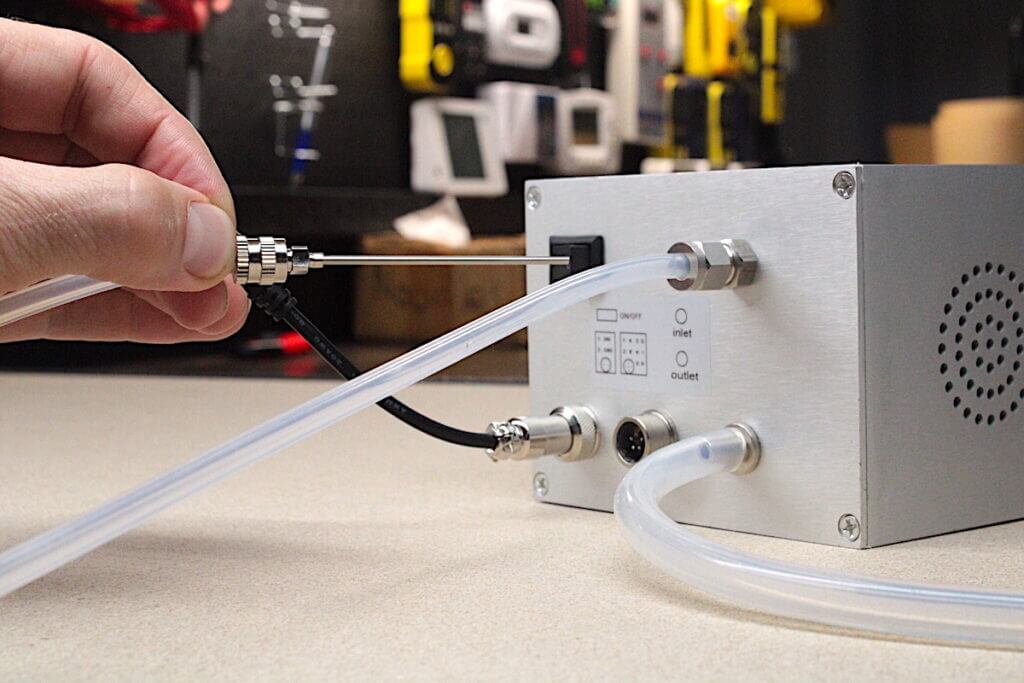

A nitrogen gas leak detector is perfect to check lines, joints, connectors, valves, spigots or part of a liquid or gas nitrogen distribution system for nitrogen leaks. These detectors require pump air, to achieve point sampling at a certain specific location. Forensics Detectors has 4 foot probes to achieve hard to reach point sampling to confirm and assess any nitrogen gas leaks.

2. Nitrogen Gas Leak Monitor

Stationary 24/7 nitrogen leak monitoring may be required for safety, by local regulations or OSHA. Please check with the appropriate authority. Continuous oxygen monitoring assures of worker, employee or technician safety when storing large amount of nitrogen in both liquid or gas form. In this case, we recommend fixed oxygen gas monitors to detect any oxygen deficiency due to nitrogen leaks or accidental spillages. These units have alarms to warn when a dangerous situation is occurring.

3. Nitrogen Portable Gas Detector for Personal Protection

Personal protection may be necessary when working with nitrogen for a prolonged period of time, in order to assess the breathable oxygen air. That means, one can place a small portable nitrogen gas detector on their shirt, belt, or bag to continuously monitor nitrogen and oxygen depletion levels. These units have alarms to warn when a dangerous situation is occurring.

How Is Nitrogen (N2) Gas Detected?

Nitrogen is detected using a measuring instrument known as a nitrogen gas detector. These devices are specific to oxygen gas, but are termed nitrogen gas detectors, since the inverse amount is oxygen. Typically, nitrogen gas detectors are composed of electronics and an oxygen sensor.

The gas sensor converts the detected oxygen gas concentration to an electronic signal for analysis by the onboard microprocessor. From there, the processor outputs the reading to the display. If the measured amount of O2 starts to decrease, then one can assume the nitrogen levels in increasing. This method of detection is known as an indicative measurement.

When oxygen depletes, it reduces past the first alarm, which is usually 19.5%, so then alarms are triggered to warn the user. Other functions, such as instructing a relay to switch on a fan or ventilation system, are also common.

Nitrogen Leak Detector Accessories?

What about Nitrogen for Cryotherapy and Oxygen Monitoring - Is It Safe?

Large amounts of nitrogen are now used in private cryotherapy spas. Ensure that an oxygen monitor is mounted, especially if the room is small and limited in ventilation. This is a real and seriously dangerous practice as highlighted by medical practitioners.

Forensics Detectors has seen this market growing, where cryotherapy spas and therapy facilities are installing oxygen depletion monitors to ensure the safety of their clients.

What Is a Portable Nitrogen Gas Detector?

A portable nitrogen gas detector is an instrument used to analyze the concentration of nitrogen / oxygen in the air and is also important to find nitrogen gas leaks.

A nitrogen gas detector is sometimes called an N2 monitor, a nitrogen sniffer, a nitrogen analyzer, or nitrogen gas tester. These names all refer to a nitrogen gas detector.

What does a Nitrogen Gas Detector Actually Measure?

Most often, a nitrogen gas detector actually measures oxygen concentrations. Nitrogen concentrations can only be correctly measured with a nitrogen gas detector (oxygen meter) (or rather oxygen rate in the air). The atmosphere has 20.9% of oxygen and about 78% of nitrogen. When detecting nitrogen gas, if the oxygen level reduces, it is reasonable to assume the nitrogen gas content is increasing beyond 78%.

Do I Need a Nitrogen Monitor when I Store Liquid Nitrogen?

Industry, factories, manufacturing, laboratories, and hospitals often use and store large quantities of nitrogen in both liquid and gas form. Liquid nitrogen is often used in cryobiology and cryotherapy.

The storage of nitrogen must be taken serious since liquid nitrogen quickly vaporizes to gas and expands at about 700 times the liquid volume. A liquid nitrogen gas leak can quickly displace oxygen in the air and may create a human asphyxiation problem.

Another problem are accidents. Liquid nitrogen is stored and transported in vessels and dewers where things may go wrong.

For example, when working with storage vials, they should be rated for cryogenic storage. Also, seals and gaskets may be compromised due to over-tightening of lids, which may promote leaking. If liquid phase storage is required, specialized storage materials such as Cryoflex tubing should be used, otherwise leaking may occur.

Given these considerable dangers, it is wise to monitor nitrogen gas or oxygen gas in nitrogen handling and storing facilities.

What About Storing CO2 and Argon Gas?

Yes, the situation is similar. When storing or handling carbon dioxide and argon gas, leaks can displace the breathable oxygen air content and create a dangerous situation. Hence, monitoring oxygen with an oxygen monitor is a excellent idea.

When an oxygen deficiency monitor is installed, the unit continuously monitors the oxygen level. For example, in a lab setting, the monitor will alarm if the oxygen level decrease. Usually the first alarm is set to 19.5%. A LED and buzzer would warn occupants to take action, and the display typical will present the quantitative results of the oxygen measurement.

Why is Nitrogen Used for Purging and Flushing?

Nitrogen is an inert gas, abundant and hence cheap. It can therefore be used to efficiently displace oxygen. For example, nitrogen is used to replace air in food packaging to extend life. Nitrogen is used in many vessels in the oil and gas industry to suppress any combustion. Nitrogen is also used in the semiconductor industry for manufacturing solid state electronics to prevent metal oxidization.

In all these examples, and most often, oxygen needs to be displaced, so in order to confirm this displacement, a nitrogen or oxygen monitor is used to provide a validation, particularly in nitrogen purge or nitrogen flush situations.

Can I Smell Nitrogen Gas?

No, nitrogen gas is not an aromatic gas and cannot be detected by the human nose.

How Does a Nitrogen Detector Work?

Again, not to get confused, when detecting nitrogen, one usually employs an oxygen electrochemical sensor cell. The alternative is to use an oxygen zirconia sensor (which is more expensive and consumes more power).

A nitrogen gas detector is composed of electronics and an oxygen sensor. The oxygen gas sensor converts the detected oxygen gas concentration to an electronic signal for analysis by the onboard microprocessor. From there, the processor outputs the reading to the display. If the oxygen levels exceed the pre-set values, alarms will be triggered to warn the user.

How Do I Select a Nitrogen Gas Detector?

To select the best nitrogen gas detector, follow this guide.

- Do I need it for nitrogen gas cylinder storage or liquid nitrogen storage? If so, your best bet is a wall-mounted nitrogen gas monitor.

- Do I need it for personal protection? If so, your best bet is a handheld nitrogen gas detector with alligator clip.

- Do I need it to detect a nitrogen leak to ensure that all my gas lines are sound and no leaks exist? If so, you need a nitrogen gas leak detector with a built in pump for point sampling.

What are the Advantages of Nitrogen as a Tracer Gas for Leak Detection?

- The advantages of using nitrogen as a tracer gas for leak detection lie in its high sensitivity, inertness, availability, cost-effectiveness, environmental friendliness, and ease of use in various systems. Nitrogen offers high sensitivity, allowing it to detect even the smallest leaks as small as 0.0005 inches, ensuring accurate and precise results.

- Nitrogen is an inert gas, meaning it does not react with other substances. This makes it safe to use in various systems and environments without the risk of chemical reactions or damage.

- Nitrogen is abundantly available and easily accessible. It can be sourced from various suppliers, making it convenient for leak detection applications.

- Nitrogen is a cost-effective option for leak detection, especially when compared to other tracer gases. Its availability and affordability make it a popular choice for many industries.

- Nitrogen is a natural component of the atmosphere and does not contribute to environmental pollution. Its use as a tracer gas for leak detection does not harm the environment or pose any health risks.

- Nitrogen leaves behind no residue after leak detection, eliminating the need for extensive cleanup or maintenance. This saves time and resources in the detection process.

How Long Does a Nitrogen Gas Sensor Last For?

Nitrogen detectors that incorporate electrochemical sensors last between 24 and 36 months. Analyzers that incorporate zirconia sensors last over 10 years.

How Do I Test My Nitrogen Gas Detector?

The best way to test your nitrogen gas detector is to expose it to a known nitrogen gas source.

Does a Real Nitrogen Sensor Exist That Actually Detects N2 Gas?

Yes. There are two varieties.

One is an ultrasonic nitrogen gas sensor. This uses the propagation of sound waves to determine the qualitative amount of nitrogen. These are reasonably priced.

Another is a thermal conductivity sensor. These are much more expensive and used for gas chromatography. These sensors are called thermal conductivity detectors (TCD) or sometimes known as katharometers. The detector changes conductivity based on the thermal properties of the gas compared to a known reference gas. From these differences, a measure of quantity can be computed.

Can You Smell Nitrogen?

Pure nitrogen gas is odorless and cannot be detected by smell. However, some nitrogen-containing compounds like ammonia have distinct, recognizable odors.

What Is a Nitrogen Gas Detector Bump Test?

- Bump testing is a procedure when one exposes the detector to a small amount of “blast” nitrogen gas to ensure the detector operates and alarms as programmed.

- The function of this test is to verify proper operation and build user confidence, particularly in hazardous applications.

- It is recommended to bump test when first purchased, followed by weekly tests. If using in LIFE-THREATENING and or DANGEROUS applications, bump test daily.

Final Words

Nitrogen (N2) gas detectors primarily function by sensing oxygen concentrations in the air, rather than directly detecting nitrogen. Gas detection focused on oxygen levels is more meaningful, as oxygen is essential for human life, and its displacement by increased nitrogen can pose serious health risks. Nitrogen, an inert gas with numerous industrial applications in both liquid and gas forms, is widely used in the oil and gas industry, food packaging, cryogenics, laboratories, and research and development. Reliable nitrogen gas detectors, typically costing less than $900, are crucial for ensuring personal protection and maintaining a safe working environment in areas where nitrogen is present, preventing the hazards associated with oxygen depletion.

About The AuthorDr. Kos Galatsis ("Dr.Koz") is the President of FORENSICS DETECTORS, where the company operates from the scenic Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years.

Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems. Dr. Koz also loves spending time with his wife and his three children going to the beach, grilling burgers, and enjoying the outdoors. Read more about Forensics Detectors here. Email: drkoz@forensicsdetectors.com

|