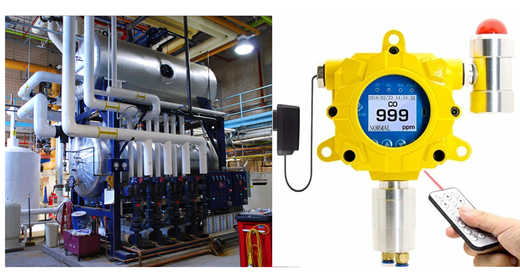

Carbon monoxide (CO) gas, a potentially deadly byproduct of boiler operation, can leak from the boiler's flue or the unit itself, creating a serious hazard in boiler rooms. Gas detection is crucial in these spaces to prevent accidents and ensure the safety of personnel. Carbon monoxide monitors specifically designed for boiler rooms are essential for alerting users when CO levels exceed safe thresholds. These detectors continuously monitor the atmosphere, providing early warnings of potential leaks. Some CO monitors can even be connected to relay controls, allowing for automatic shutdown of the boiler when dangerous levels of carbon monoxide are detected. By implementing reliable CO gas detection in boiler rooms, facilities can protect their employees and assets from the life-threatening consequences of carbon monoxide leaks.

Pros |

Cons |

|

✅ Carbon monoxide can be dangerous and potentially fatal. Carbon monoxide monitors can protect from any unintentional CO leaks. ✅ Carbon monoxide monitors are relatively inexpensive. ✅ Carbon monoxide monitors are readily available and can help provide early warning to a CO problem |

⛔ Boiler rooms often leak carbon monoxide gas. ⛔ Boiler rooms have high BTU burners and hence, large volumes of exhaust gases that can quickly inundate a indoor space. ⛔ Carbon monoxide monitors require maintenance such as checking their operation, calibration or sensor end of life. |

Best Carbon Monoxide Detector for Boiler Rooms?

A Carbon Monoxide Monitor for a boiler room needs to be fixed to the wall and have a loud siren and light alarm. The unit should be robust and handle any tampering or knocks and bumps. It should be much more robust than a CO detector made for a home setting.

- It should comply with any state or local requirements such as those in Texas. As an example, Texas code requires:

- CO Detector with Interlock to shut the burners (via gas valve operation) at 50ppm.

- Turn off the burners when loss of power to the CO Detector.

- To be versatile, it would be best if the carbon monoxide monitor was programmable, so that the alarm points can be set at the correct values as recommended by your local or state authorities (or if they modify), they can be changed in the future.

Some excellent carbon monoxide monitor options include the following:

- Forensics Detectors' Carbon Monoxide Wall Monitor

- Macurco Carbon Monoxide Fixed Gas Detector

- BW Technologies' Fixed Carbon Monoxide Monitor

- RKI Carbon Monoxide Fixed Wall Monitor

- AGS Carbon Monoxide Monitor

Why do I need a Carbon Monoxide Monitor in my Boiler room?

A properly kept, efficiently operating boiler produces extremely little amounts of CO, but a badly maintained boiler can produce lethal levels.

High BTU burners in boiler rooms produce significant volumes of exhaust gases, which can quickly flood an indoor environment.

Carbon monoxide exhaust gas can leak via a few modalities which includes:

- cracked heater exchange

- back drafting

- poor exhaust venting

- poor appliance installation or maintenance

Furthermore, you may be needed to have a CO monitor in your boiler room as mandated by the local or state authorities.

Are Carbon Monoxide Detectors Required in Boiler Rooms?

Yes.

As of September 1st, 2020, both a carbon monoxide detector and interlock system are now required to be installed in boiler rooms in certain states like that adopted by Texas. Check with your state and local code if your boiler rooms must have such a carbon monoxide detector and interlock system.

Trigger alarm set point is at 50ppm aligned with the Occupational Safety and Health Administration’s (OSHA) Permissible Exposure Limit (PEL) for carbon monoxide. Trigger alarm means the CO concentration at which the burners must be disabled.

For compliance to Texas Boiler Code, a latching relay is required. When the CO Wall Mount unit does switch (alarm mode), the in-series latching relay will ensure the boiler remains OFF until a human has reset it. This unit alone does not have a "memory relay", only an ordinary relay. So please plan to have your installer or electrician also install a latching relay with the FD-60-CO unit.

What is a Carbon Monoxide Monitor?

A carbon monoxide monitor is a sensing device used to measure the amount of carbon monoxide in a given area. The unit measures carbon monoxide gas in air with a scale of parts per million, abbreviated as ppm.

Who Needs a Carbon Monoxide Detector in a Boiler Room?

A number of different individuals may benefit from using a carbon monoxide detector, especially where boiler rooms are involved.

Homeowners (small)

Homeowners may benefit from using a carbon monoxide detector, especially if they have a home boiler room. These can be used to prevent against a potential disaster if the boiler begins to leak carbon monoxide gas by alerting the homeowner if this is the case. For home settings, a low level CO detector would be functionally effective and cost effective.

Industry, Business, Schools, Maritime, Buildings (large)

Some businesses and industrial settings have dedicated boiler rooms. If this is the case, business owners should take the proper precautions to install a carbon monoxide detector in these rooms to protect themselves, their employees, and their customers. Local codes are requirements should be searched as these may change or new rules adopted (have specific CO monitor requirements, alarm points, functions, interlocks, etc..)

An Industrial Fixed Wall Carbon Monoxide Monitor that is able to continuously monitor the boiler rooms environment with industrial specification is recommended.

Where Should a Carbon Monoxide Detector Be Located in a Boiler Room?

- Since air mixes with carbon monoxide, the monitor should be placed in a location that best represents the air one would breath when in the main area of the boiler room.

- A location where there is easy visual to the CO monitor and physical access for maintenance.

- Away from moving objects, moving people, doors or draft points (vents, windows, etc...)

- Do not install within 5 ft. of the boiler.

- Do not install near vents, flues, chimneys or any forced/unforced air ventilation openings.

- Do not install near ceiling fans, doors, windows or areas directly exposed to the weather so external air, water or rain reaches the alarm.

- Do not install in dead air spaces, such as peaks of vaulted ceilings or gabled roofs, where CO may not reach the sensor in time to provide early warning.

- Do not install on a switched or dimmer-controlled outlet.

- Do not obstruct the sensor port of the CO monitor. Do not place the alarm where furniture or other objects block the flow of air to the vents.

How Long Do Carbon Monoxide Detectors Last?

The majority of carbon monoxide detectors can last from 2-5 years. Special calibrations procedures may be required. To the obvious and follow manufacturer's recommendations. Carbon Monoxide sensors (see below) all have a limited lifetime between 2 to 10 years, but please, double check your specific product.

Have Leaking Gases in Boiler Rooms Hurt People?

Yes, they have even killed people.

In fact, a woman in Norfolk, Virginia succumbed to carbon monoxide poisoning as a result of a boiler leaking the carbon monoxide gas.

What Causes High Carbon Monoxide Readings on a Boiler?

- When boilers report high carbon monoxide readings, it is often due to unbalanced combustion that occurs as a result of an excess of gas or air.

- Another potential cause is a lack of combustion air due to limited fresh air intake.

- Degradation of the burners over time is also a common problem.

- Poor or neglected maintenance.

How Can I Tell if My Boiler is Leaking Excess Carbon Monoxide?

A combustion analyzer should be used to detect excess carbon monoxide output from a boilers/

- A combustion analysis to analyze CO emission levels (ultimate quantitative measurement).

- A stove's gas flame is yellow (tell tale sign).

- Soot being present (tell tale sign).

- The boiler's pilot light is unable to remain on, indicating a draft problem (tell tale sign).

What Should I Do if the Carbon Monoxide Detector in My Boiler Room Goes Off?

If a CO alarm occurs in a boiler room, take the following action:

- Immediately move occupants to fresh air outdoor or open all doors or windows to ventilate the area and allow the carbon monoxide to disperse.

- Where possible, if not already done so, safely turn off fuel burning appliance. Evacuate the building and call 911.

- Do not re-enter the premises nor move away from the open door or window until emergency services responders have arrived, the premises have been aired out, and your alarm remains in its normal condition.

- Seek medical help immediately for anyone suffering from the symptoms of headache, drowsiness, nausea, etc.

- Do not use the appliances again until they have been checked by a qualified technician and the fault located and cleared.

Can a Leaking Boiler Explode?

Boilers can, in fact, explode.

Typically, this is not due to gas leaks, and is instead attributable to pressure, heating, or weakness of boiler components.

Can You Smell Carbon Monoxide In A Boiler?

No, carbon monoxide is completely odorless and undetectable by human senses. This makes it extremely dangerous - always use a carbon monoxide detector near boilers.

Final Words

Carbon monoxide (CO), a potentially lethal gas, can be produced in boiler rooms through various means and must be constantly monitored to ensure safety. Gas detection is crucial in these environments, as CO leaks can occur from the boiler's flue or the unit itself, posing a serious threat to human life. Carbon monoxide detectors, also known as CO meters or monitors, are essential for continuously monitoring the presence of this dangerous gas in boiler rooms. Some local or state authorities even mandate the installation of CO detectors in these spaces. By implementing reliable carbon monoxide gas detection, facilities can protect their employees and assets from the deadly consequences of CO exposure, ensuring a safer working environment.

About the Author

Dr. Kos Galatsis ("Dr.Koz") is the President of FORENSICS DETECTORS, where the company operates from the scenic Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years.

Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems. Dr. Koz also loves spending time with his wife and his three children going to the beach, grilling burgers, and enjoying the outdoors.

Read more about Forensics Detectors here.

Email: drkoz@forensicsdetectors.com

Phone: +1 424-341-3886